Components make Shadows

Components make Shadows- Vision systems use various modes of lighting for component analysis. Some modes cast significant shadows helping or complicating the testing process. Tall components such as this coil may also profit from angled views of the solder fillets (joints) providing another component is not shadowing or obstructing the viewing angle.

- In regard to shadowing this can be an important consideration. Orprovision's AOIs even perform shadowing calculations automatically for the programmer. Your PCB designs should consider the immediate area surrounding tall components as not suitable for components that are critical to test.

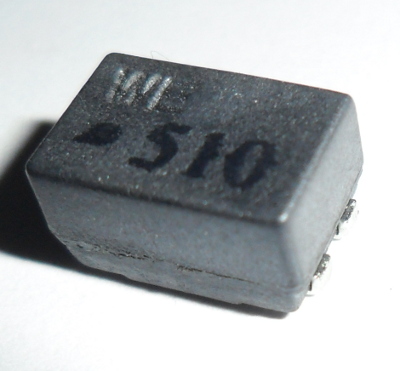

- ICs and various other components are often tested with angled cameras. Recently I had 2 of the Wurth coils shown here to test. They were positioned end to end and close together making testing of the solder joints between the two components impossible. Application specialists from the company Orprovision have told me their systems are not capable anyways to test these solder fillets even in optimal conditions. If the coils were positioned side by side I can achieve good testing with a Viscom AOI if the incident angle of 45 degrees or so is not abstructed.

- Incident angles for most AOI manufactures are approxiametly 45 degrees to the vertical from all four poles of the compass or even in 45 degree steps. The company Göepel offers a 360 degree possibility giving the programmer many more possibilities to test difficult areas.